catalog : https://book.yunzhan365.com/jrlbf/yqjf/mobile/index.html

video: https://studio.youtube.com/video/cawAYBuL1SQ/edit

Why we need clear piping leakage and corrosion band protectors

Piping clear leakage band protectors made from materials like PVC, VCI (Vapor Corrosion Inhibitor), and FEP (Fluorinated Ethylene Propylene) are used for several important reasons:

In summary, piping clear leakage band protectors made from PVC, VCI, and FEP provide crucial benefits in terms of leak prevention, durability, visibility, safety, and cost efficiency. They are designed to handle various challenging conditions and protect both the piping system and the environment from potential hazards.

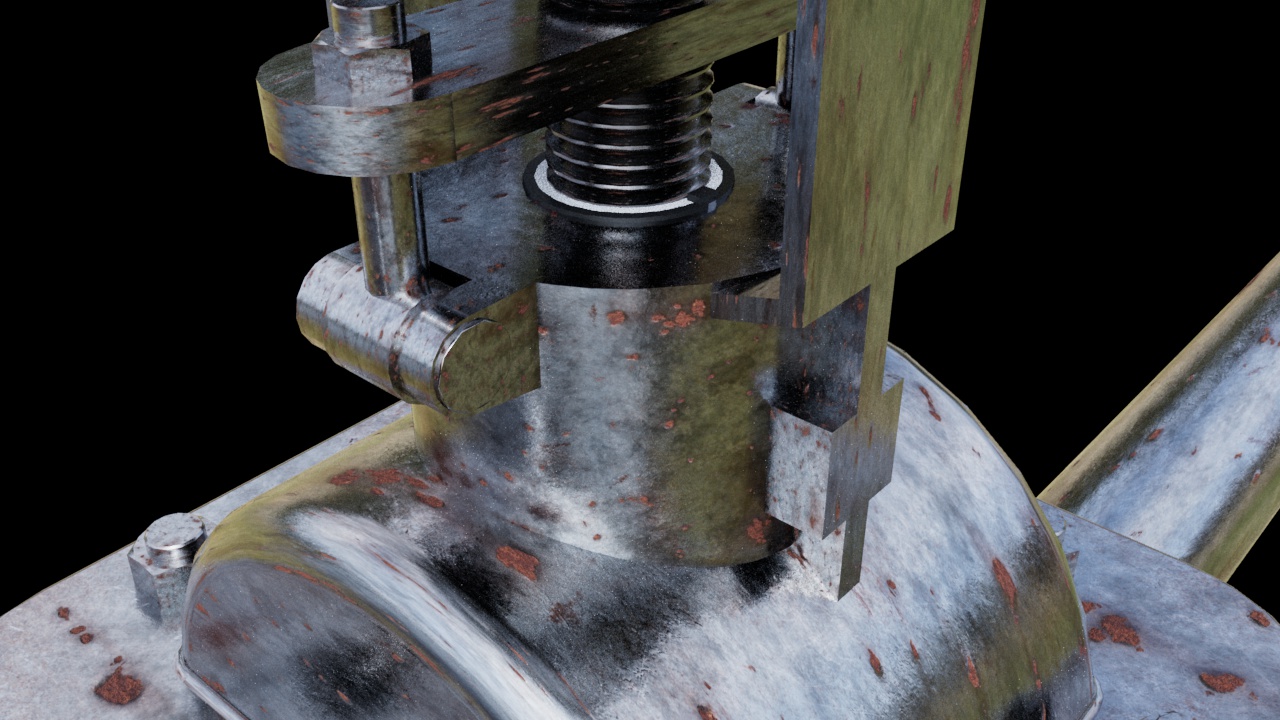

2.VCI rubber Magnetic VOCs Fugitive Emission Protection O ring band

1. Overview of VCI Rubber Magnetic O-Ring Bands

VCI (Volatile Corrosion Inhibitor):

Rubber Magnetic O-Ring Bands:

O-rings made from rubber and infused with magnetic properties provide an effective sealing mechanism. The magnetic aspect allows for easy installation and alignment, ensuring a tight seal when placed in their designated grooves.

2. Functionality and Importance

Fugitive Emission Protection:

Fugitive emissions refer to the unintended release of gases or vapors from equipment. In many industries, especially those dealing with volatile compounds, managing these emissions is crucial for environmental compliance and operational efficiency.

O-ring bands help seal connections in storage tanks and valves, significantly reducing the potential for leaks and thus minimizing fugitive emissions.

VOCs (Volatile Organic Compounds):

3. Applications

Stem Valves:

Design: Stem valves regulate fluid flow within a tank or piping system. They have a moving stem that opens or closes the valve.

Sealing: Incorporating VCI rubber magnetic O-ring bands into the design enhances sealing performance, preventing leaks from the valve stem area.

Storage Tanks:

Usage: Storage tanks are used in various industries (petroleum, chemical, food processing) for holding liquids and gases.

Vapor Control: Proper sealing with VCI rubber magnetic O-rings minimizes the risk of fugitive emissions, thus maintaining the integrity of stored substances and ensuring compliance with environmental regulations.

4. Benefits of Using VCI Rubber Magnetic O-Ring Bands

Corrosion Resistance: VCI properties protect metal components from rust and corrosion, extending the lifespan of storage tanks and valves.

Leak Prevention: The magnetic O-ring bands provide a robust seal, which is essential for preventing leaks and emissions of VOCs.

Ease of Installation: The magnetic feature allows for easy installation and alignment of the O-rings, reducing downtime during maintenance or repairs.

Environmental Compliance: Using these seals contributes to meeting regulatory requirements concerning VOC emissions, protecting both the environment and public health.

5. Industry Standards and Compliance

Industries dealing with VOCs must adhere to local, national, and international regulations concerning emissions. This often includes guidelines from agencies like the Environmental Protection Agency (EPA) in the U.S. and the European Union’s REACH regulation.

6. Conclusion

VCI rubber magnetic O-ring bands represent an innovative solution for industries that require effective sealing mechanisms to prevent fugitive emissions and manage VOCs. Their unique properties help ensure corrosion resistance, enhance sealing performance in stem valves, and maintain environmental compliance in storage tanks. For specific product specifications, installation guidelines, or further inquiries, you may want to consult with manufacturers or suppliers specializing in VCI technology and sealing solutions.

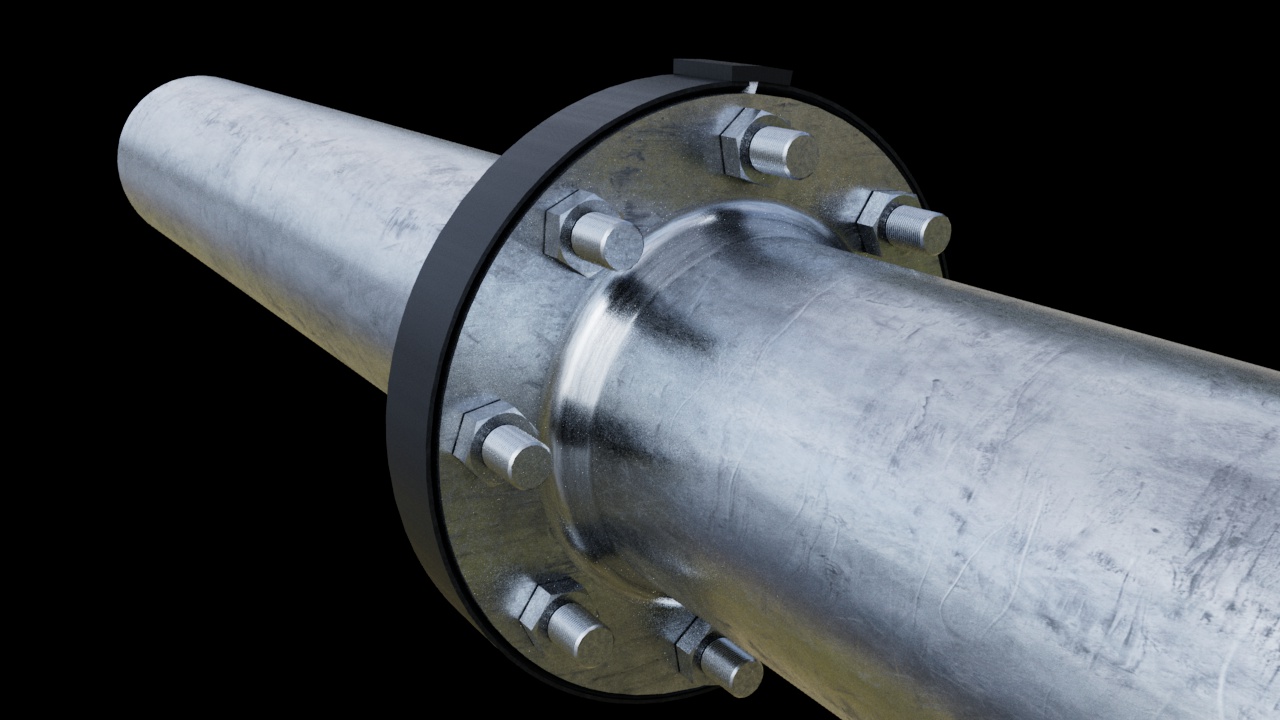

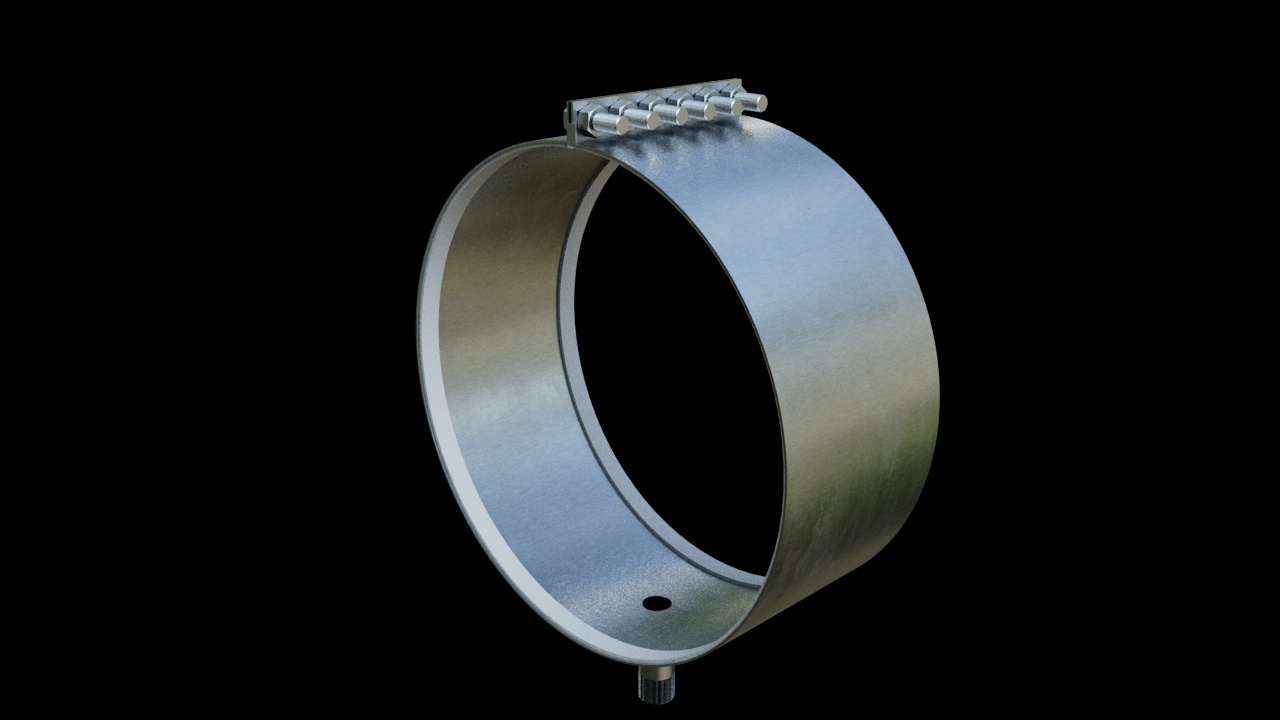

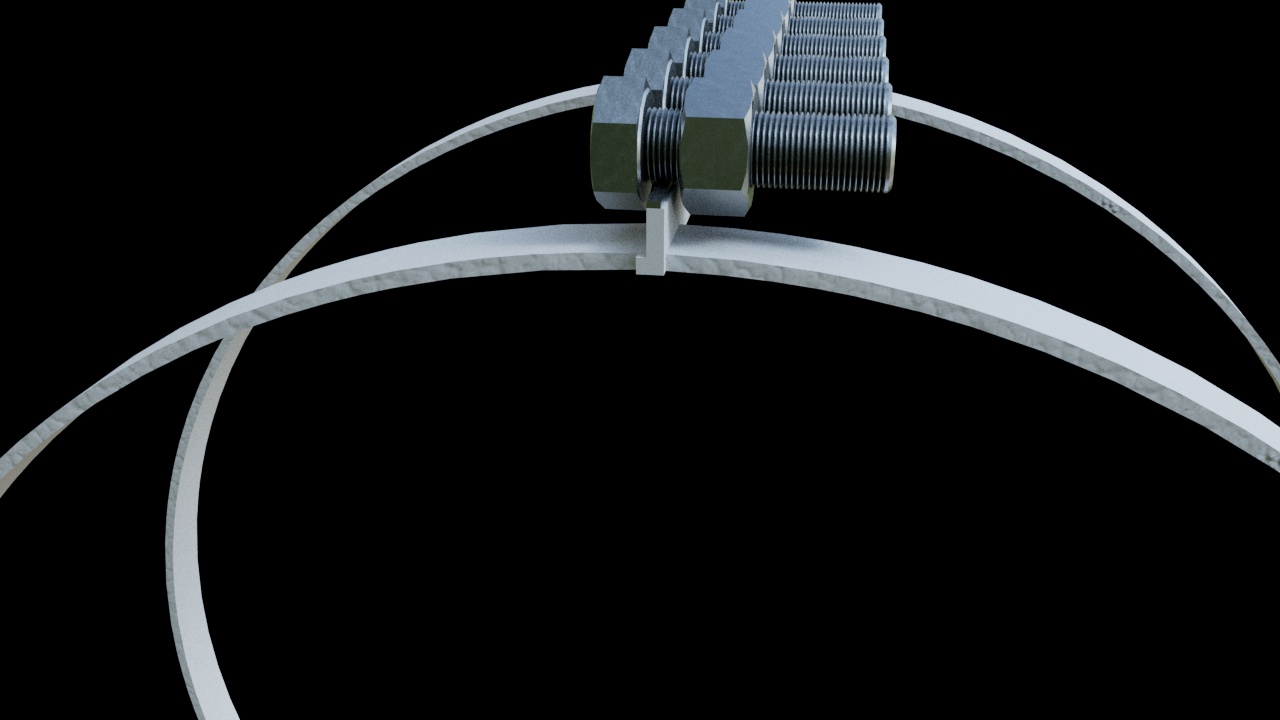

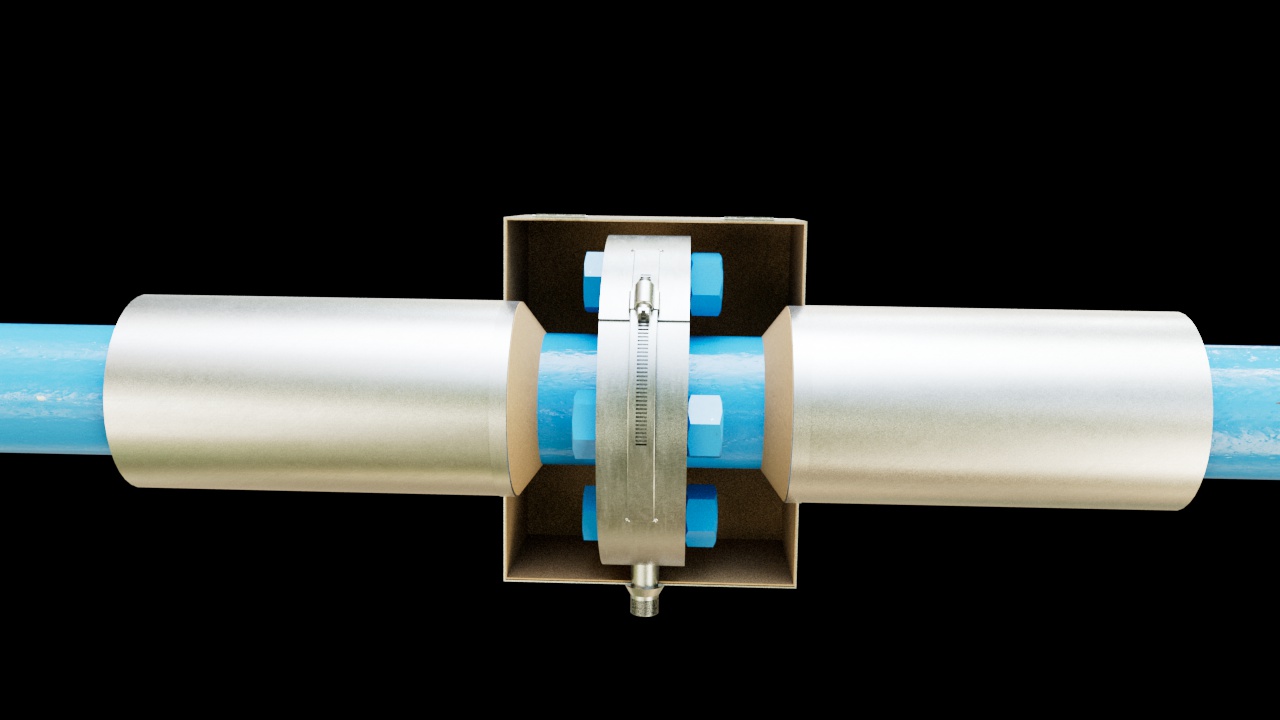

3. SUS 316L Flange band protectors with expanded PTFE gasket tape for sealing. For chemicals, LNG, cryogenic temperature

Material Composition

Gasket Material

Drain Pipe Feature

Industries

Design Features

Preparation

Application of Gasket Tape

Assembly

Testing

Regular Inspections

Replacement Procedures

SUS 316L flange band protectors with expanded PTFE gasket tape represent a robust solution for sealing in demanding environments, particularly in applications involving chemicals, LNG, and cryogenic temperatures. By ensuring high-quality materials, proper installation, and regular maintenance, these systems can provide reliable and safe operation under the specified conditions, including temperatures ranging from -196 °C to +270 °C and pressures up to 50 bar. Implementing these guidelines will help optimize the performance and longevity of your sealing system.

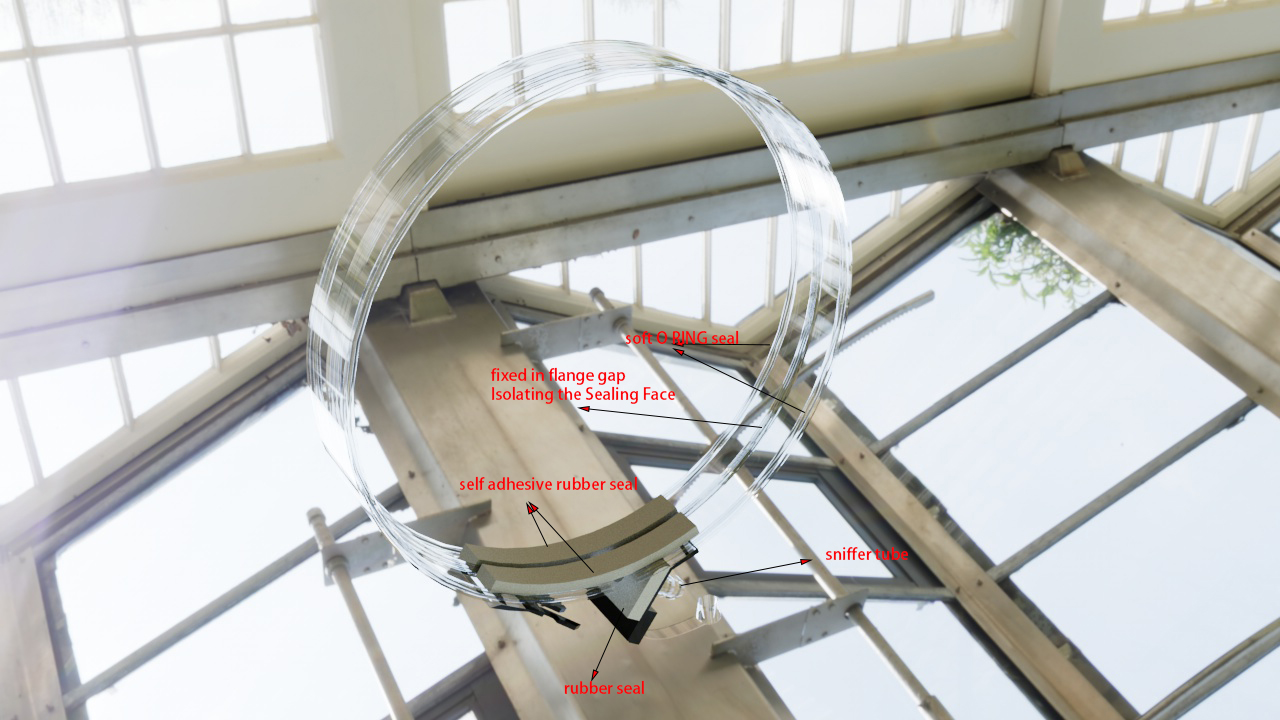

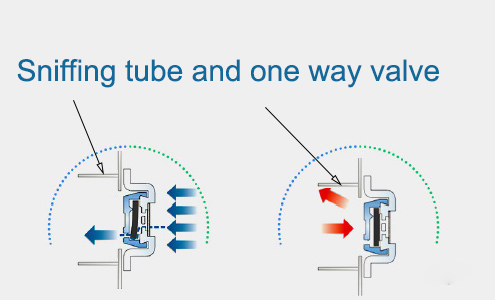

4.VCI one way valve flange and vlave leaks cover with drain tube

1. One-Way Valve

Function: A one-way valve allows fluid (such as water vapor) to flow in only one direction. This is critical for preventing backflow and maintaining the integrity of the system.

Benefits:

Prevents Contamination: It ensures that outside contaminants, such as rainwater, cannot enter the pipeline or the VCI cover.

Pressure Regulation: By allowing vapor to escape, it helps to relieve any pressure buildup within the cover, which can occur due to temperature changes or other factors.

2. Sniffing Tube

Function: A sniffing tube is often used for monitoring the environment within a sealed space. It can be equipped with sensors to detect gas concentrations or changes in pressure.

Benefits:

Leak Detection: The sniffing tube allows for the detection of leaks by monitoring the vapor levels or pressures inside the pipeline. Any changes can indicate a leak.

Real-Time Monitoring: Continuous monitoring helps in maintaining the safety and efficiency of the pipeline.

3. VCI Cover with Rubber Seal

Function: The VCI cover is designed to provide a protective environment for metal components by emitting corrosion-inhibiting vapors. The rubber seal ensures a tight closure.

Benefits:

Corrosion Protection: VCI releases molecules that form a protective layer on metal surfaces, preventing corrosion.

Water Resistance: The rubber seal, combined with a heat-sealable seal, prevents rainwater from entering the cover, thus protecting the equipment inside.

Enhanced Durability: The heat-sealable seal further ensures that the cover is secure and resistant to environmental factors.

4. Heat-Sealable Seal

Function: A heat-sealable seal creates a strong bond between the cover and the surface it encloses, enhancing the airtightness of the setup.

Benefits:

Improved Seal Integrity: It reduces the chances of leaks and ensures that the VCI remains effective over time.

Ease of Installation: Heat sealing can be a quick and efficient method of creating a secure seal.

Overall Benefits

Water Protection: This system effectively prevents rainwater from entering, protecting the pipeline from moisture-related issues.

Vapor Pressure Relief: The design allows for the release of water vapor pressure, minimizing the risk of damage or corrosion due to condensation.

Leak Detection: The setup enables early detection of pipeline leaks, allowing for timely maintenance and repairs.

Corrosion Inhibition: VCI technology helps maintain the integrity of the pipeline, reducing maintenance costs over time.

Conclusion

This integrated approach of using a one-way valve, sniffing tube, VCI cover, rubber seal, and heat-sealable seal creates a robust system for protecting pipelines from environmental factors while allowing for effective monitoring and maintenance. It's an excellent method for extending the life of pipeline infrastructure and ensuring operational efficiency.

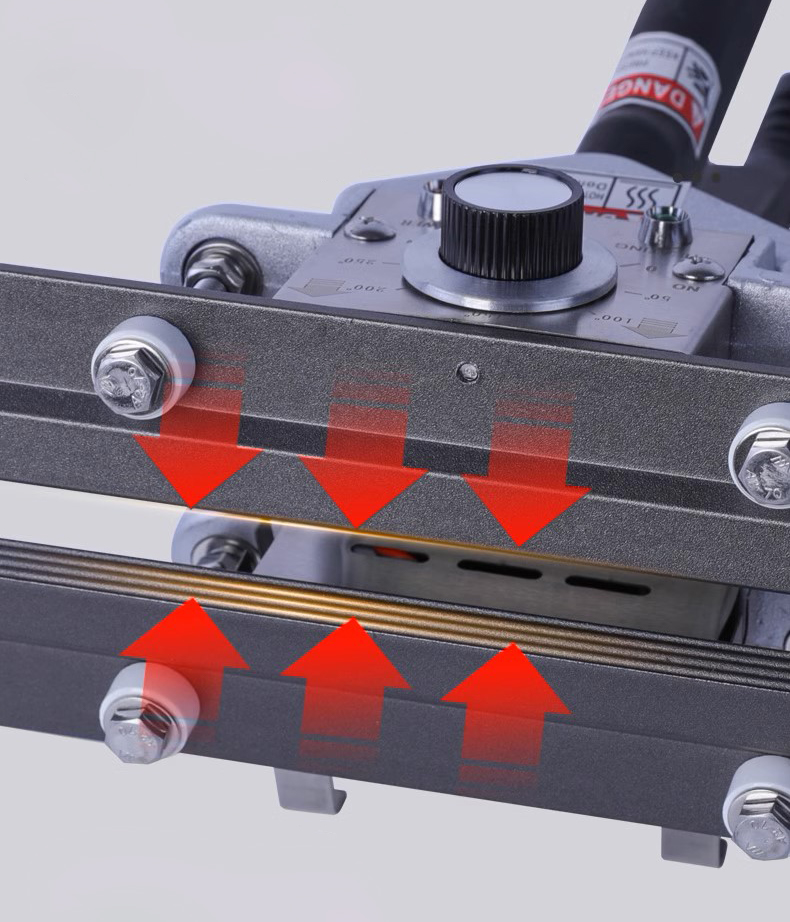

5.Flange ePTFE cover with sniffing tubes for insulated flanges or valve leak detection

sing a flange band with expanded PTFE (ePTFE) and sniffing tubes is an effective solution for insulated flanges or valve leak detection in various industrial applications. Below is a detailed explanation of the components, their functions, and the benefits they provide in these systems.

Components Overview

Flange Band with ePTFE

Material: Expanded PTFE is a versatile material known for its excellent chemical resistance, thermal stability, and sealing properties.

Design: The flange band can wrap around insulated flanges or valves to create a secure and effective seal.

Properties:

Chemical Resistance: ePTFE is inert to many chemicals, making it suitable for harsh environments.

High Temperature Resistance: It can withstand high temperatures, maintaining integrity in various applications.

Low Friction: ePTFE has low friction properties, which can facilitate easier installation and reduce wear.

Sniffing Tubes

Functionality: Sniffing tubes are small, often flexible tubes designed to monitor the atmosphere around a specific area, such as a flange or valve.

Applications: They can be equipped with sensors to detect gas leaks, pressure changes, or other environmental conditions.

Leak Detection: By sampling air from around the flange or valve, sniffing tubes can quickly identify the presence of gases that may indicate a leak.

Applications

Insulated Flanges

Insulation Purpose: Insulated flanges are used to prevent thermal bridging and maintain temperature control in piping systems. They are commonly found in applications like steam lines, hot water systems, or any system requiring thermal insulation.

Use of ePTFE Bands:

Wrapping insulated flanges with an ePTFE band enhances the thermal insulation by providing a tight, impermeable seal.

This configuration helps in preventing moisture ingress, which can lead to corrosion and thermal loss.

Valve Leak Detection

Critical Monitoring: In many industrial settings, detecting leaks from valves or flanges is crucial for safety and efficiency.

Integration with Sniffing Tubes:

The sniffing tubes can be installed near valves or flanges to continuously monitor for leaks.

If a leak occurs, the tube will draw air from the area and send it to a sensor, which can detect specific gases or changes in pressure.

This allows for immediate identification of issues, enabling quick corrective action.

Benefits of the System

Enhanced Sealing and Protection:

The combination of the ePTFE band and insulation ensures that the flange or valve is protected against moisture, temperature fluctuations, and chemical exposure, significantly reducing the risk of corrosion and damage.

Effective Leak Detection:

Sniffing tubes provide a proactive approach to leak detection, allowing for real-time monitoring. This is especially important in high-pressure or hazardous systems where leaks can pose serious safety risks.

Increased System Longevity:

By preventing corrosion and maintaining optimal operating conditions, this setup contributes to the longevity of the piping system and its components, reducing maintenance costs over time.

Versatility:

ePTFE can be used across a wide range of industries, including oil and gas, chemical processing, food and beverage, pharmaceuticals, and more.

Installation Considerations

Preparation:

Ensure that the flange surface is clean and free of any debris or old gasket materials before installation.

Inspect the ePTFE band and sniffing tubes for any signs of damage prior to installation.

Installation Process:

Wrap the ePTFE band securely around the insulated flange, ensuring that it is tightly fitted to form a seal.

Install the sniffing tube in a location that effectively samples the atmosphere around the flange or valve. Ensure that it is connected to the monitoring equipment.

Testing:

After installation, conduct a leak test by pressurizing the system to ensure that the seal is effective and that there are no leaks detected by the sniffing tubes.

Conclusion

Integrating a flange band with ePTFE and sniffing tubes for insulated flanges or valve leak detection is a robust solution for ensuring the integrity of piping systems in various industrial applications. This system not only provides excellent sealing and protection against environmental factors but also enhances safety through effective leak monitoring. By employing these technologies, industries can improve operational efficiency and reduce the risk of costly downtime or hazardous incidents.

catalog online:https://book.yunzhan365.com/jrlbf/vetd/mobile/index.html

|

|

|

|

|

|

|

|

© 2022 Wenzhou Leakage Corrosion Hardware Products Co., Ltd All Rights Reserved. http://www.flangesprayshields.com/ Main products: Flange guards with drain | Flange spray shields | Valve fugitive emission system