e catalog :https://book.yunzhan365.com/raywz/kdkh/mobile/index.html

https://book.yunzhan365.com/jrlbf/ylfl/mobile/index.html

https://book.yunzhan365.com/jrlbf/ylfl/mobile/index.html

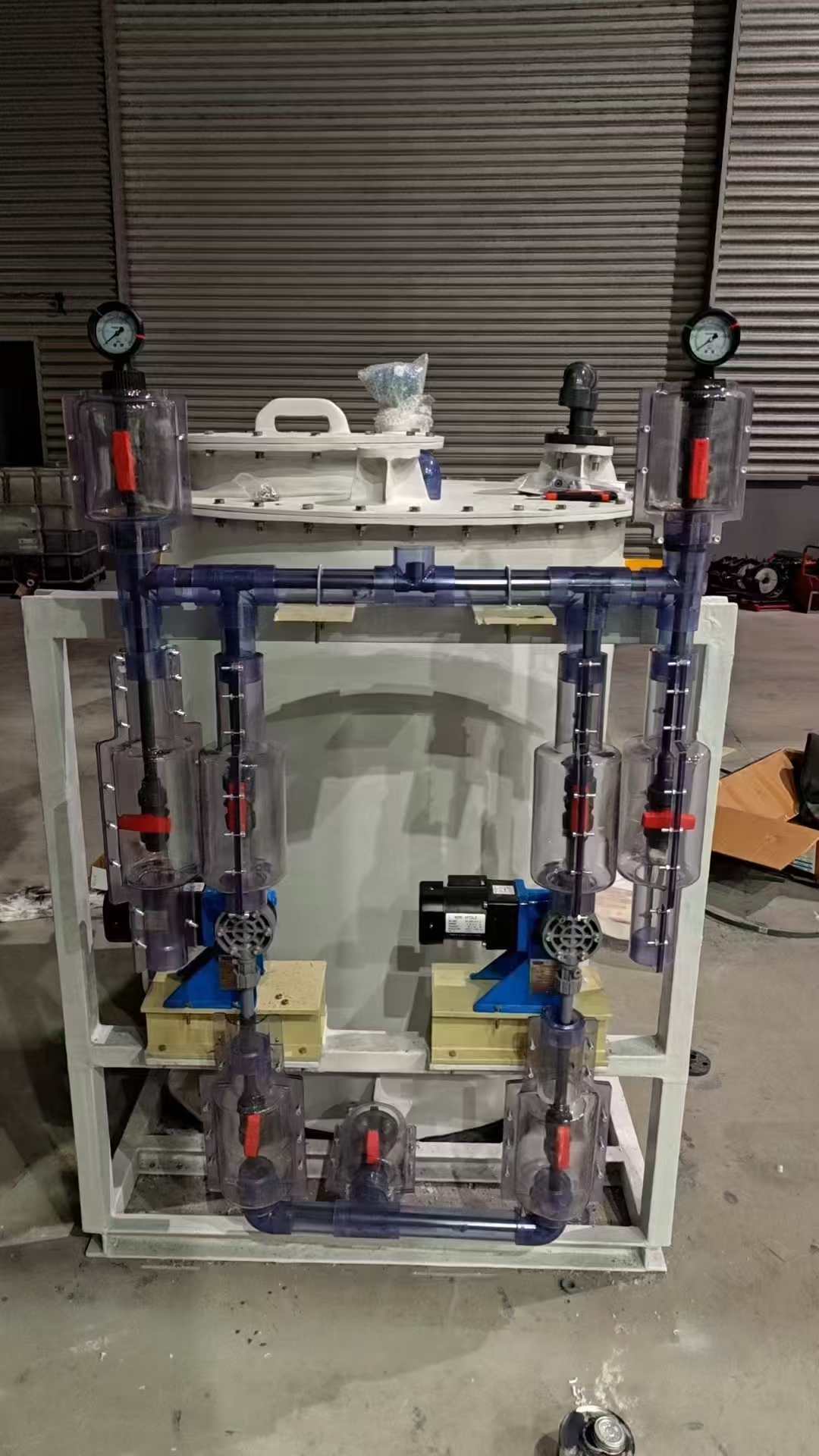

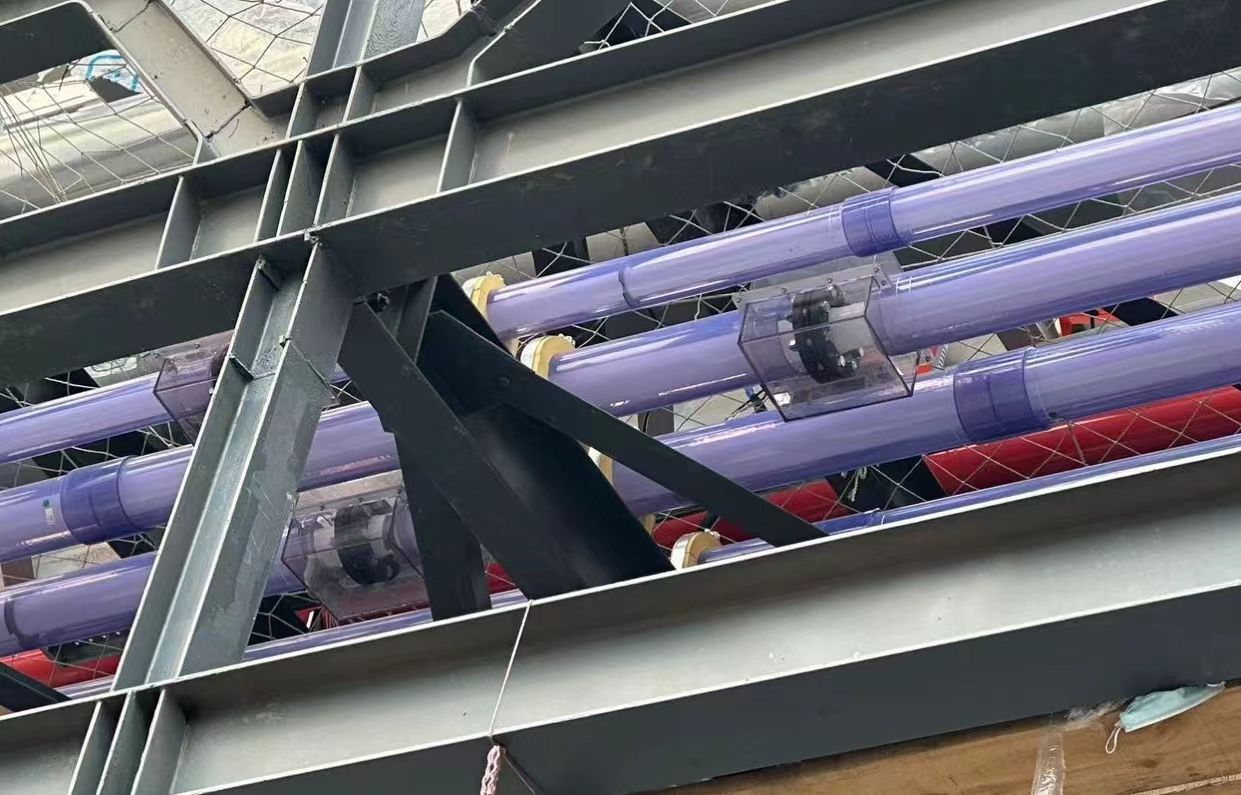

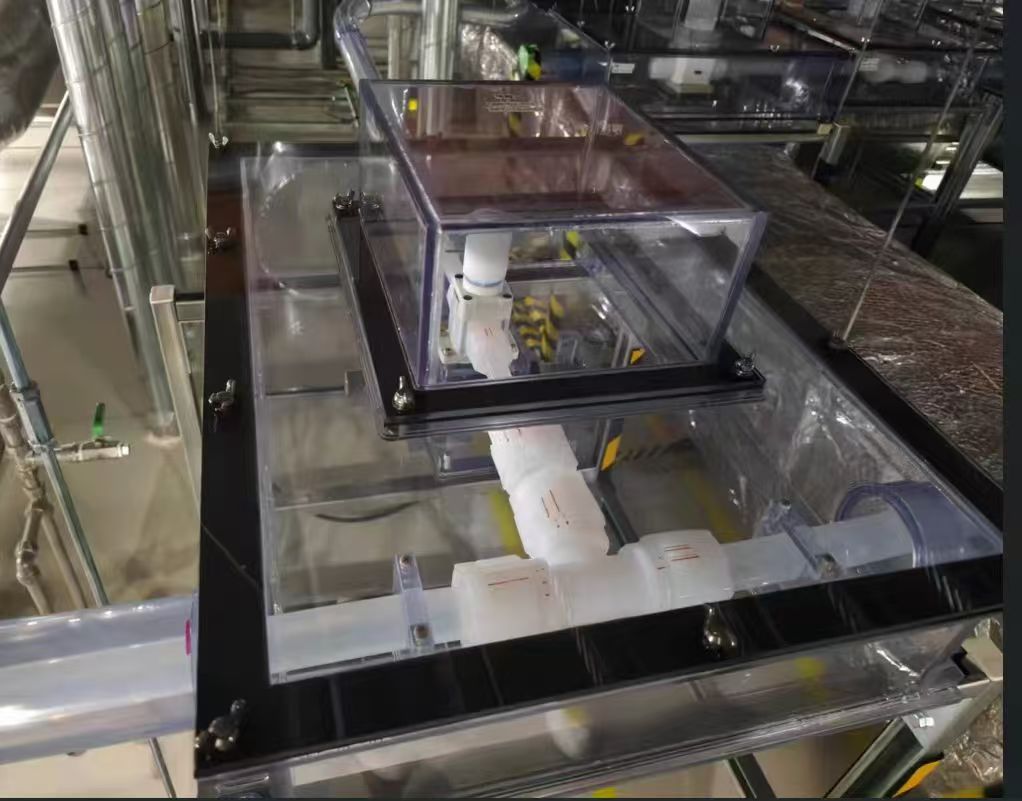

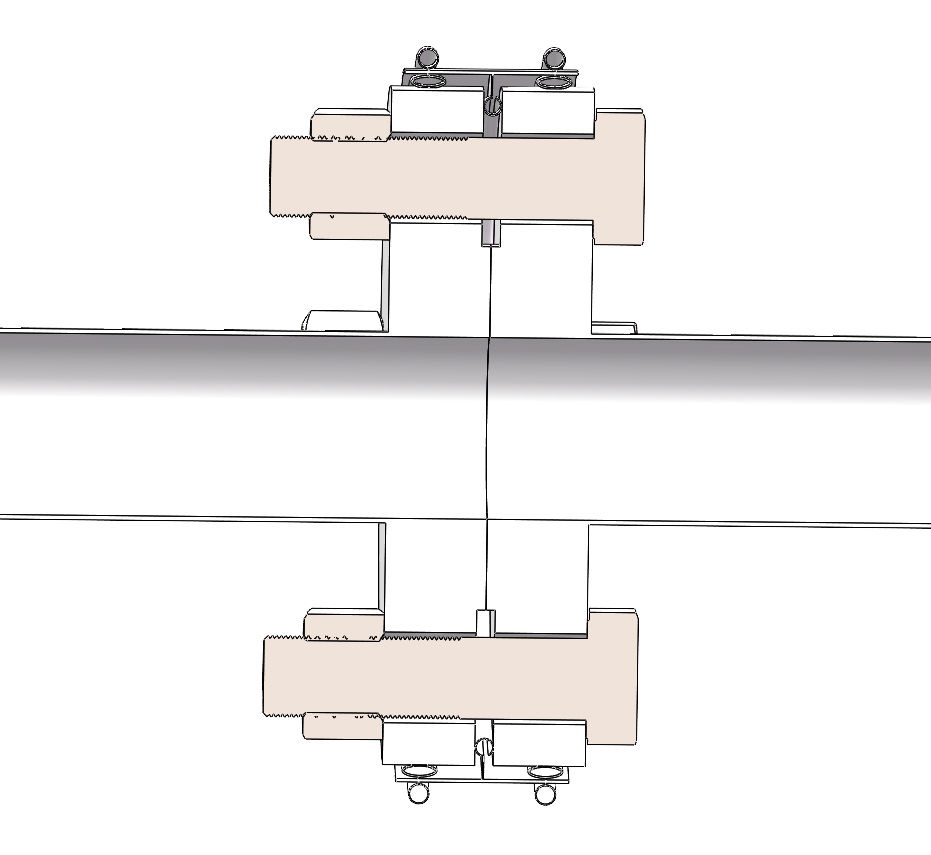

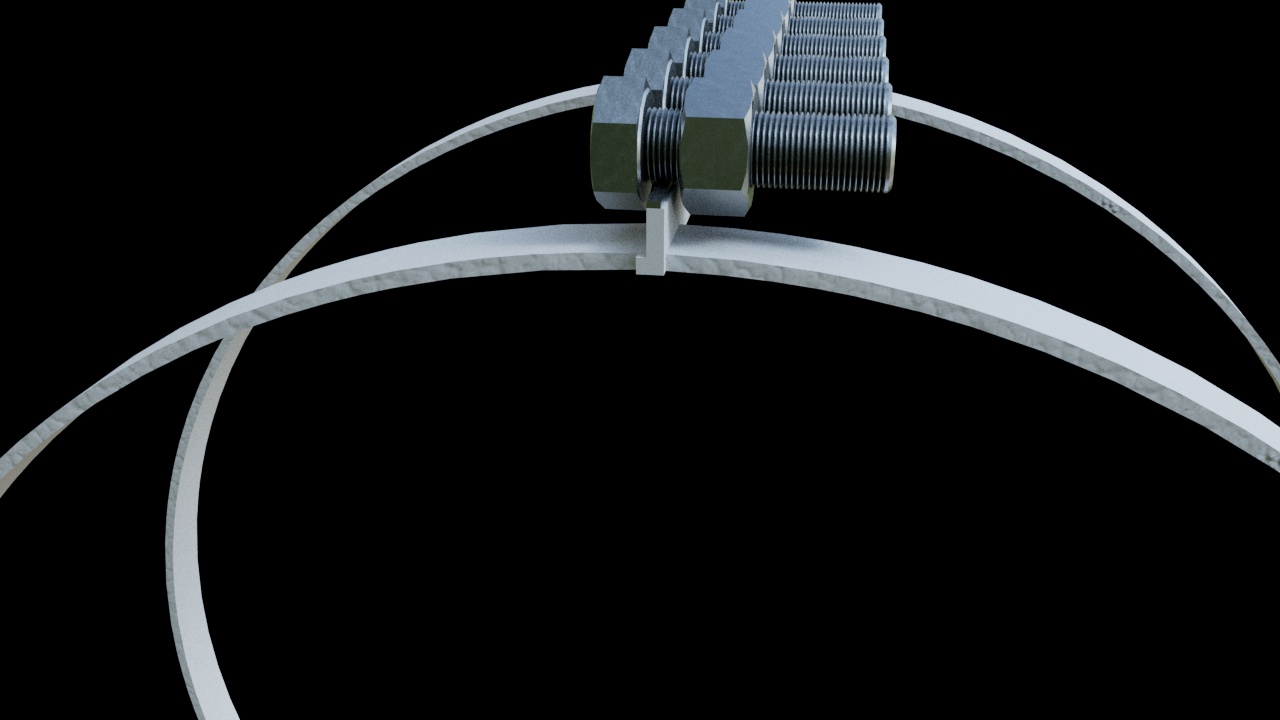

What is Clear double containment piping system

lear UPVC double containment piping system is a specialized type of piping used for transporting hazardous or sensitive liquids, gases, or chemicals in industries such as pharmaceuticals, food processing, and chemicals. It is designed to prevent leakage and ensure safety by providing a secondary containment layer around the primary pipeline.

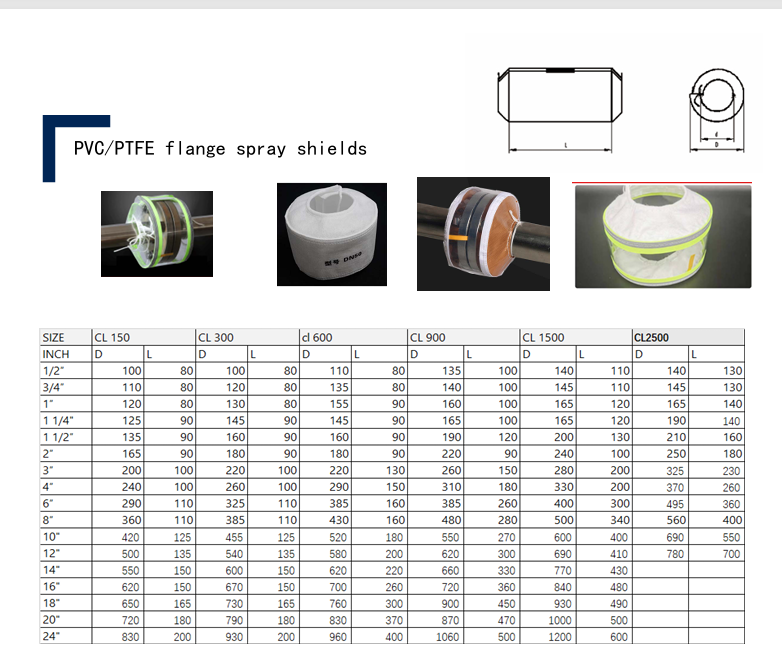

What is standward size for ANSI flange guards in Chinese standard

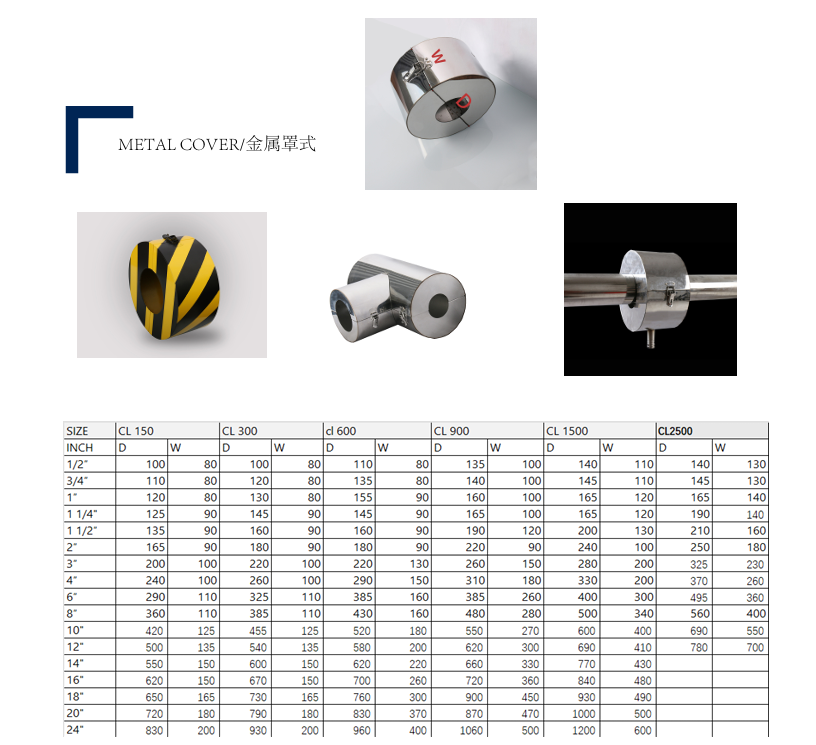

What is metal flange guards standwards

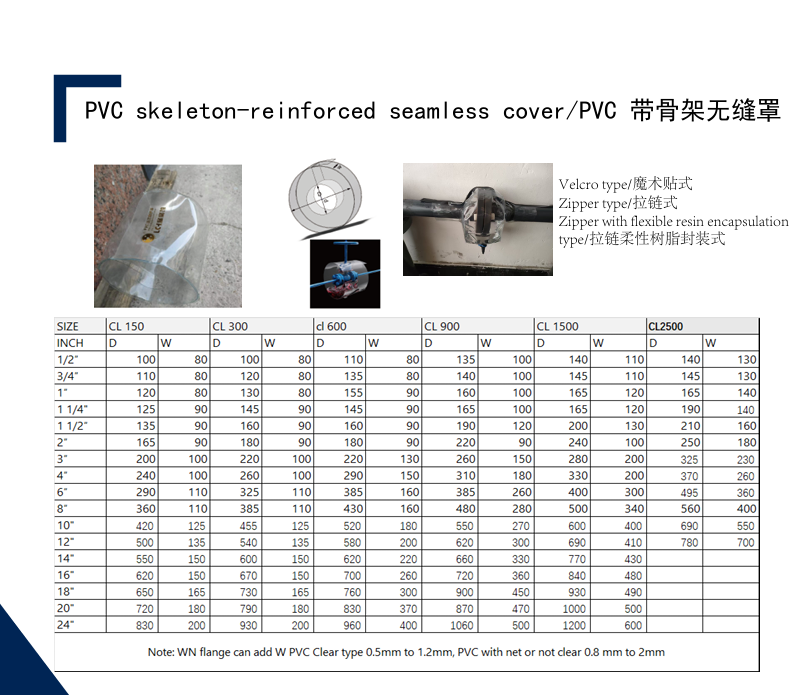

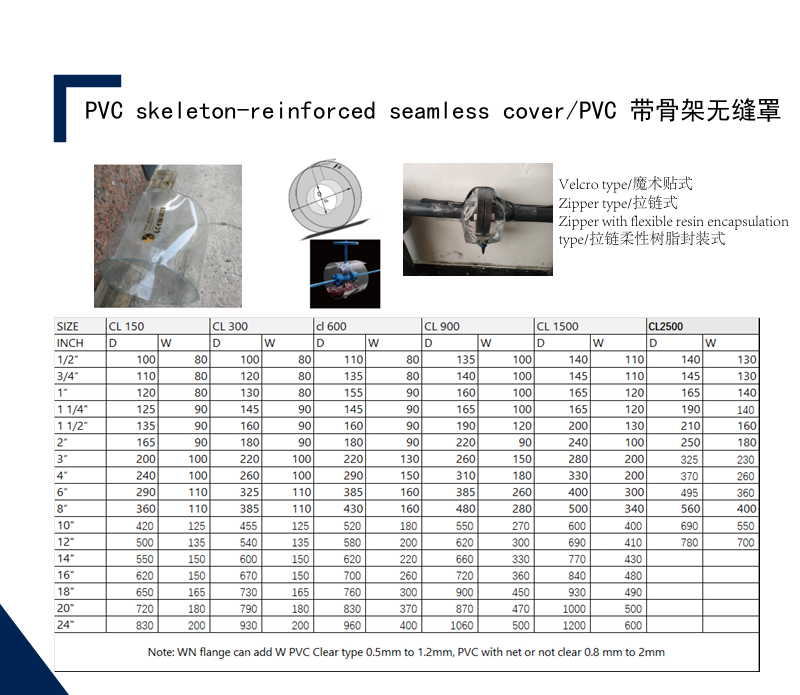

What is PVC flange contain cover size?

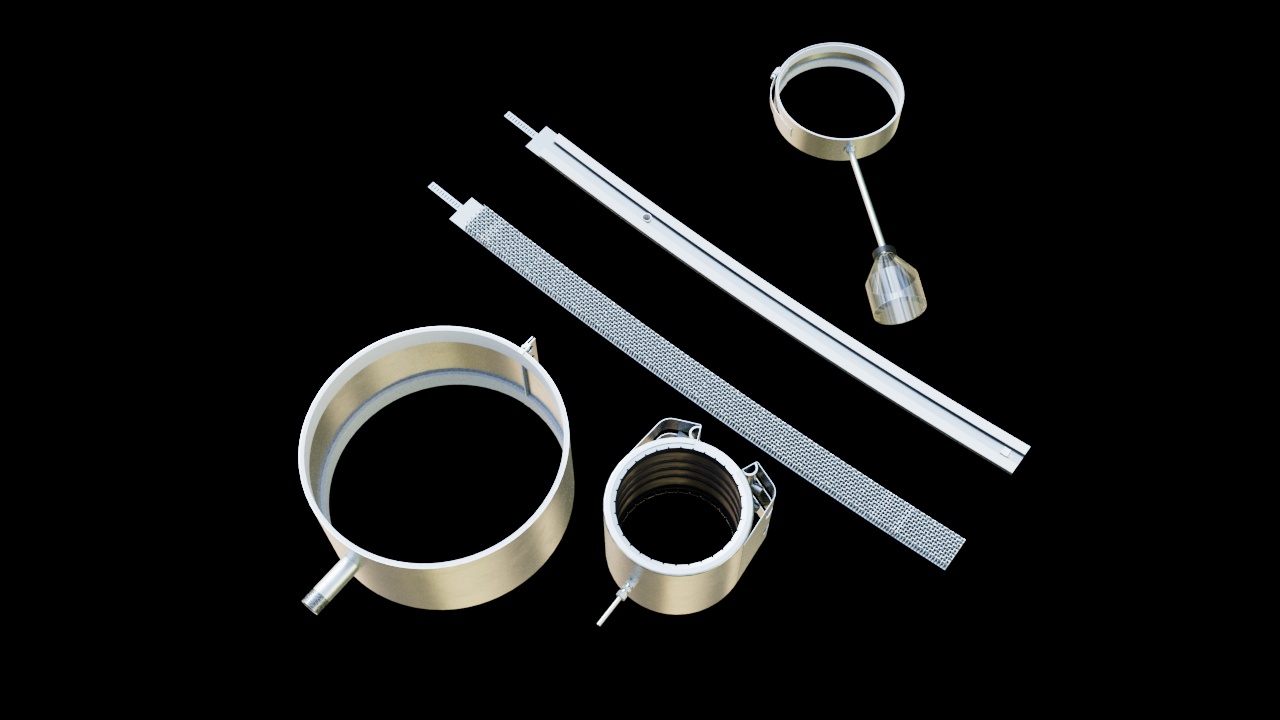

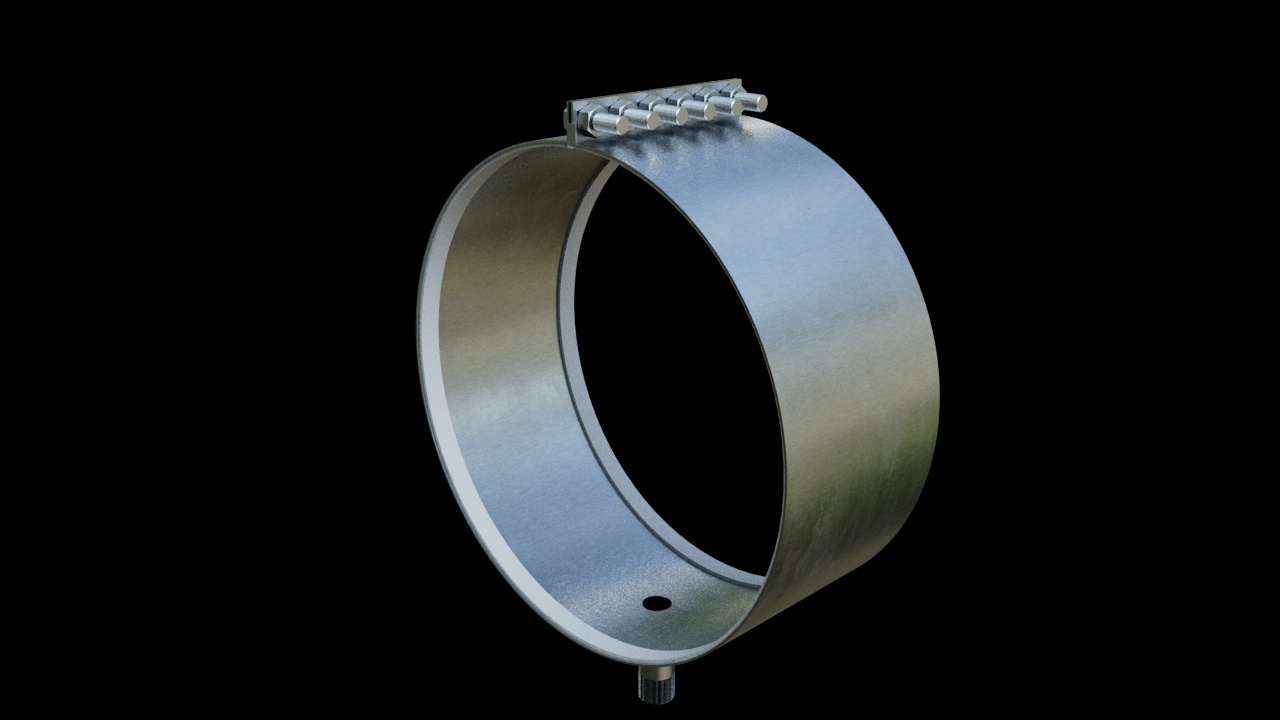

Why we need clear piping leakage and corrosion band protectors

Piping clear leakage band protectors made from materials like PVC, VCI (Vapor Corrosion Inhibitor), and FEP (Fluorinated Ethylene Propylene) are used for several important reasons:

In summary, piping clear leakage band protectors made from PVC, VCI, and FEP provide crucial benefits in terms of leak prevention, durability, visibility, safety, and cost efficiency. They are designed to handle various challenging conditions and protect both the piping system and the environment from potential hazards.

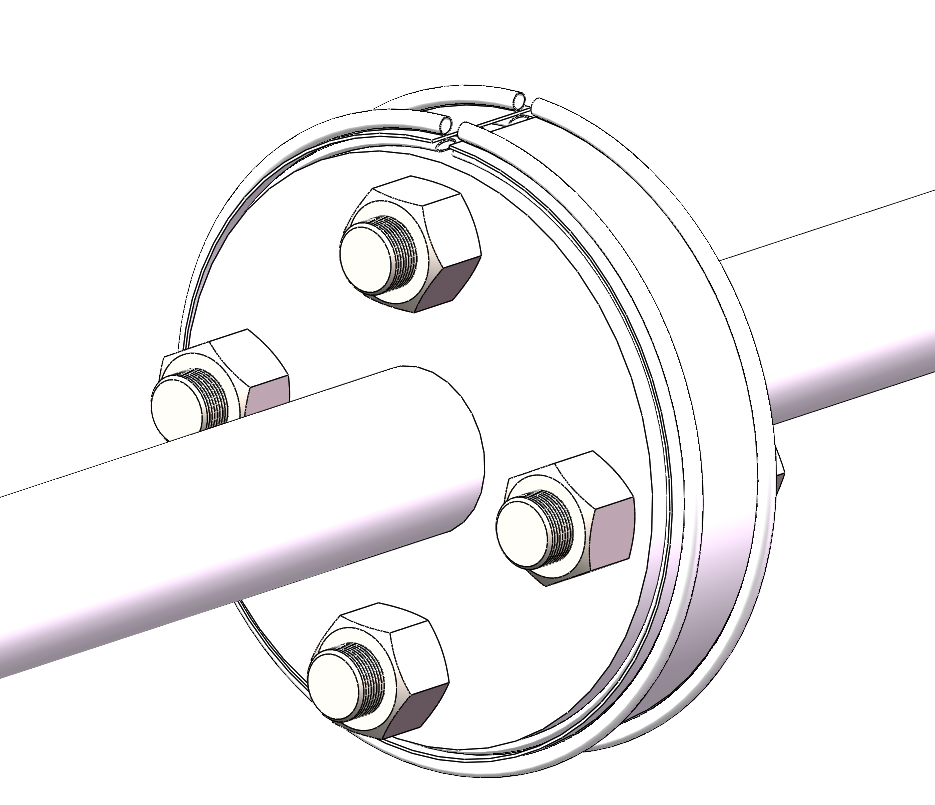

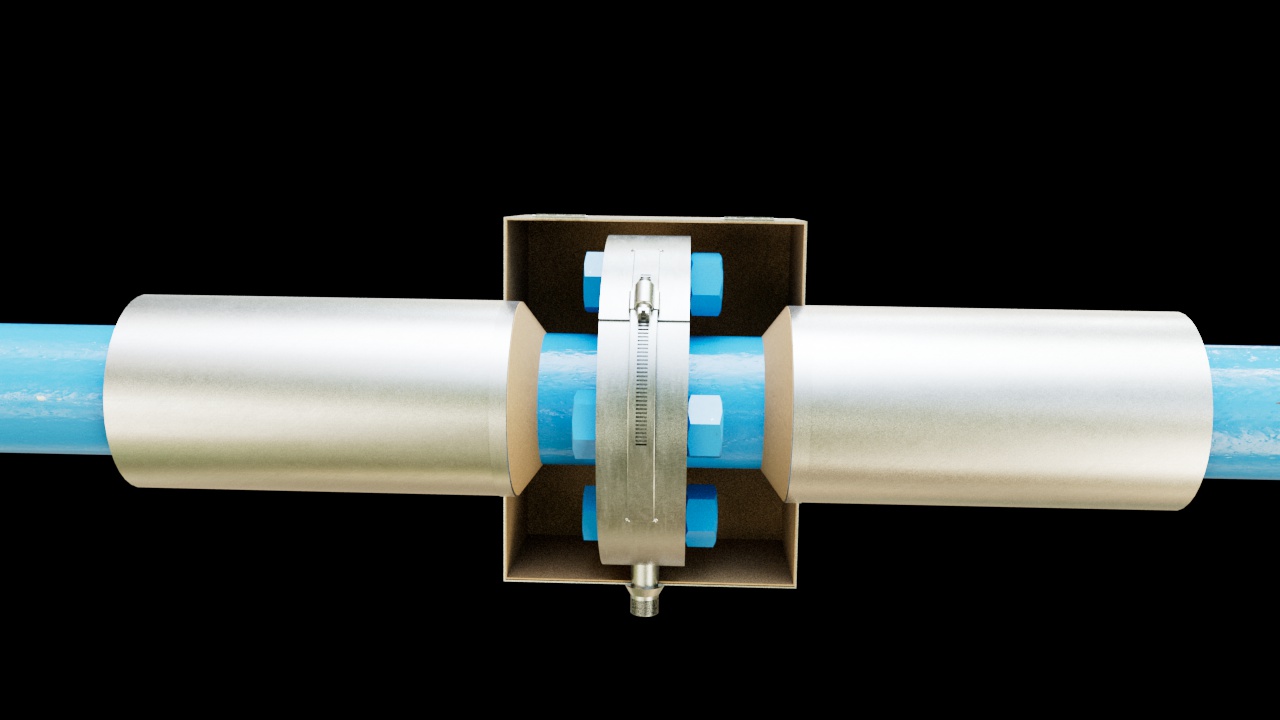

3. SUS 316L Flange band protectors with expanded PTFE gasket tape for sealing. For chemicals, LNG, cryogenic temperature

Material Composition

Gasket Material

Drain Pipe Feature

Industries

Design Features

Preparation

Application of Gasket Tape

Assembly

Testing

Regular Inspections

Replacement Procedures

SUS 316L flange band protectors with expanded PTFE gasket tape represent a robust solution for sealing in demanding environments, particularly in applications involving chemicals, LNG, and cryogenic temperatures. By ensuring high-quality materials, proper installation, and regular maintenance, these systems can provide reliable and safe operation under the specified conditions, including temperatures ranging from -196 °C to +270 °C and pressures up to 50 bar. Implementing these guidelines will help optimize the performance and longevity of your sealing system.

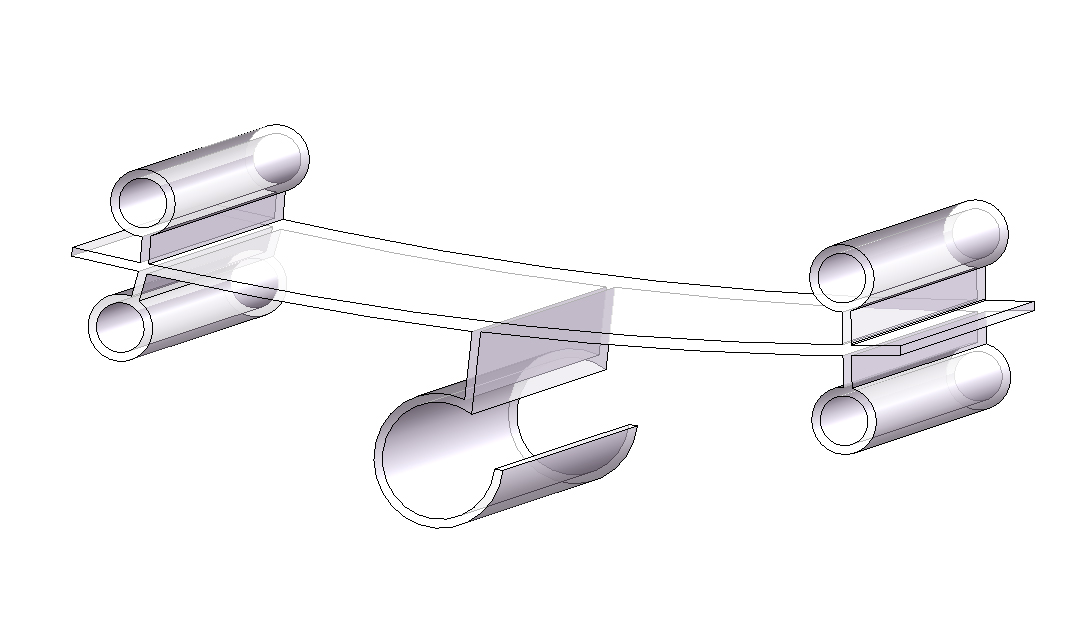

Components Overview

Flange Band with ePTFE

Material: Expanded PTFE is a versatile material known for its excellent chemical resistance, thermal stability, and sealing properties.

Design: The flange band can wrap around insulated flanges or valves to create a secure and effective seal.

Properties:

Chemical Resistance: ePTFE is inert to many chemicals, making it suitable for harsh environments.

High Temperature Resistance: It can withstand high temperatures, maintaining integrity in various applications.

Low Friction: ePTFE has low friction properties, which can facilitate easier installation and reduce wear.

Sniffing Tubes

Functionality: Sniffing tubes are small, often flexible tubes designed to monitor the atmosphere around a specific area, such as a flange or valve.

Applications: They can be equipped with sensors to detect gas leaks, pressure changes, or other environmental conditions.

Leak Detection: By sampling air from around the flange or valve, sniffing tubes can quickly identify the presence of gases that may indicate a leak.

Applications

Insulated Flanges

Insulation Purpose: Insulated flanges are used to prevent thermal bridging and maintain temperature control in piping systems. They are commonly found in applications like steam lines, hot water systems, or any system requiring thermal insulation.

Use of ePTFE Bands:

Wrapping insulated flanges with an ePTFE band enhances the thermal insulation by providing a tight, impermeable seal.

This configuration helps in preventing moisture ingress, which can lead to corrosion and thermal loss.

Valve Leak Detection

Critical Monitoring: In many industrial settings, detecting leaks from valves or flanges is crucial for safety and efficiency.

Integration with Sniffing Tubes:

The sniffing tubes can be installed near valves or flanges to continuously monitor for leaks.

If a leak occurs, the tube will draw air from the area and send it to a sensor, which can detect specific gases or changes in pressure.

This allows for immediate identification of issues, enabling quick corrective action.

Benefits of the System

Enhanced Sealing and Protection:

The combination of the ePTFE band and insulation ensures that the flange or valve is protected against moisture, temperature fluctuations, and chemical exposure, significantly reducing the risk of corrosion and damage.

Effective Leak Detection:

Sniffing tubes provide a proactive approach to leak detection, allowing for real-time monitoring. This is especially important in high-pressure or hazardous systems where leaks can pose serious safety risks.

Increased System Longevity:

By preventing corrosion and maintaining optimal operating conditions, this setup contributes to the longevity of the piping system and its components, reducing maintenance costs over time.

Versatility:

ePTFE can be used across a wide range of industries, including oil and gas, chemical processing, food and beverage, pharmaceuticals, and more.

Installation Considerations

Preparation:

Ensure that the flange surface is clean and free of any debris or old gasket materials before installation.

Inspect the ePTFE band and sniffing tubes for any signs of damage prior to installation.

Installation Process:

Wrap the ePTFE band securely around the insulated flange, ensuring that it is tightly fitted to form a seal.

Install the sniffing tube in a location that effectively samples the atmosphere around the flange or valve. Ensure that it is connected to the monitoring equipment.

Testing:

After installation, conduct a leak test by pressurizing the system to ensure that the seal is effective and that there are no leaks detected by the sniffing tubes.

Conclusion

Integrating a flange band with ePTFE and sniffing tubes for insulated flanges or valve leak detection is a robust solution for ensuring the integrity of piping systems in various industrial applications. This system not only provides excellent sealing and protection against environmental factors but also enhances safety through effective leak monitoring. By employing these technologies, industries can improve operational efficiency and reduce the risk of costly downtime or hazardous incidents.

catalog online:https://book.yunzhan365.com/raywz/kdkh/mobile/index.html

|

|

|

|

|

|

|

|

© 2022 Wenzhou Leakage Corrosion Hardware Products Co., Ltd All Rights Reserved. http://www.flangesprayshields.com/ ![]()